Abiding by all efforts for customers’ success and customer first principle, Beijing KUNYOU Pharmatech Co., Ltd. provide top quality products and services. We provide tooling and spare parts for all kinds of softgel main machines. We provide state of the art die rolls for all kinds of softgel machines. We not only offer our clients production equipment and tooling soft capsule, but the complete solution of soft capsule production.

Beijing KUNYOU Pharmatech Co., Ltd., which is established in 2008, has been focusing on designing, manufacturing and selling pharmaceutical machinery, food machinery and paintball machinery.

KUNYOU Pharmatech provides various models of Softgel Encapsulation Machines (soft capsule encapsulation machine, paintball machine, soft gelatin capsule machine), such as S406 with 6" dies, the medium size S407 with 7.5" dies and the latest and largest S610 with 10"dies. Here, you can find whatever paintballs and soft capsules that you need. Welcome to Beijing KUNYOU Pharmatech Co., Ltd. We look forward to cooperating with you!

After more than ten years of unremitting efforts, our continuing research and cooperation with many domestic and foreign pharmaceutical factory, plant health products and paintball production factory, not only enable us to make a lot of technical innovation in soft capsule equipment in animal gel and Vgel, but also to accumulate rich experience in the production process of soft capsule. After years of great efforts and cooperation with world wide pharmaceutical companies, neutraceutical companies and paintball companies, numerous of improvements were made. We also have rich experience in softgel formulation and manufacturing process. We have three sets of high accuracy CNC milling machine, together with lathe, grinding machine, EDM machine, wire cutting machine, we can make state-of-the-art equipments and softgel die roll.

Questions to Vgel

What is a Vgel?

A Vgel is a type of softgel that is commonly used as an oral dosage form for medicine or supplements. Their smooth surface makes even large softgels easier to swallow and are durable, reliable, and popular with consumers. Softgels consist of a gelatin shell surrounding a liquid or paste fill. The softgel shell is a combination of gelatin, water, opacifier and a plasticiser such as glycerin or sorbitol. Common softgel gelatin shells are made from pork, bovine, or fish derivatives. Growing consumer markets wish to avoid consuming such gelatin for any number of reasons including religious, cultural, or vegetarian concerns. To meet those needs, Vgel shells are becoming more and more popular as they are made from plant sources or ingredients such a tapioca (starch).

Vgel formulations come in different varieties – Which one is right for you?

Popular Vgel shells are made from ingredients such as tapioca or seaweed. While both work effectively in encapsulation and can be marketed to Vgel target markets, tapioca is generally less expensive and easier to work with. Thus budget limitations that have been the primarily barrier of whether or not to add vgel products to your product line are now easier to accommodate. CapPlus can easily connect you to a newly available starch formula that is less expensive and requires no contract.

How are Vgels made?

Softgels are produced in a process known as encapsulation using a rotary die encapsulation process. Two flat ribbons of gelatin are brought together on a twin set of rotating dies. The dies contain recesses manufactured to a specific size and shape (oval, oblong, etc) which cut out a two-dimensional shape in the gelatin ribbon and form a seal where the two sides meet. As the die begins to cut out the shape in the gelatin ribbon a precise dose of fill material is injected causing the two flat ribbons to expand into the die pockets. After which the dies rotate and seal the fill in the gelatin form. Vgel formulas are thicker in viscosity than standard gelatin and specific equipment is needed to manage the temperature changes required during the production process.

How much does it cost to make Vgels?

Depending on how many Vgels you want to make determines the size and speed of the softgel encapsulator you will need. CapPlus has encapsulation systems to suit every need – from start-up, to R&D, to high volume production. This setup can range from under $200,000 to over $1M.

Where do I get the ingredients?

Upon purchase of a softgel encapsulation system we can provide you with vgel material providers.

What equipment do I need?

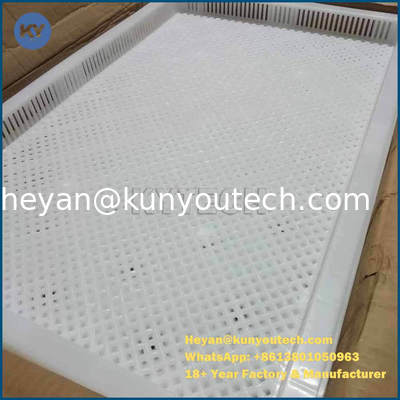

To make Vgels you will need a softgel encapsulator, tooling (rotating dies in the sizes and shapes you need), a gel melting system, gel melting tank(s), fill transfer tank(s), chiller, and tumble dryers. You may also need auxiliary equipment such as color mixing systems, drying trays and dollies, drying tunnels, stone mill, vacuum homogenizer, visual inspection, sorting, and polishing machines, etc.

CapPlus provides softgel encapsulation equipment specifically designed for Vgel formulations. We can also connect you to a newly available Vgel formula that is less expensive and requires no contract. The combination of these two solutions will help you easily and economically make Vgels.

Can I use my current softgel production equipment for Vgel production?

Yes. Vgel specific modifications can be made and Vgel specific equipment can be purchased so that you can easily convert your standard softgel encapsulator to a dual softgel/Vgel encapsulator. You may also want to strongly consider dedicating an encapsulator to Vgel specific production in order to meet growing Vgel market demand.

Vgel marketplace & opportunities

Softgels are an increasingly popular dosage form, especially in the fast growing nutricuetical market. Vgels enable you to meet this demand with a non-animal shell that will satisfy your customers' vegetarian, religious, and cultural needs

Brass Tacks - What does it take to start Vgel production?

Vgel production equipment and formulas are available today. Contact CapPlus today for a recommendation based on your budget and production needs.

Can I get financing?

Yes. We offer financing through a partner. Why worry about depleting your budget when it only takes dollars a day for you to get started.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!