Automatic Softgel Capsule Machine , medicine packaging machine High speed

S403 Softgel Encapsulation Machine

Productivity of Machine:

22,800 capsules/hour (8# OV, 4 RPM),

12,960 capsules/hour (20# OB, 4 RPM)

Function of Machine:

1.The gelatin ribbon is lubricated by micro lubricating technology to lower the consumption of

lubrication oil, the capsules are washing free and the drying time can be reduced remarkably.

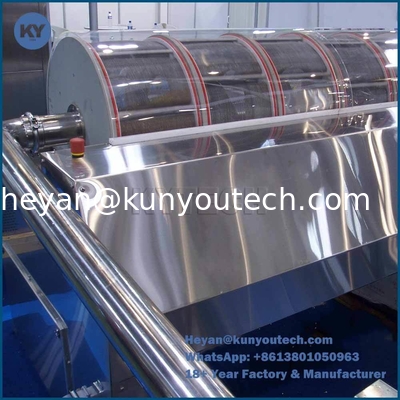

2.The main moving parts adopt Swiss precise bearings. The gelatin ribbon drum assembly and mangle

roller are driven by independent motors, which are synchronized electronically. The noise is lowered

and it works more stable. By utilizing separate lubrication for medicine pump assembly and die roll

housing assembly, the waring is effectively reduced, which extends the failure-free operation time further.

3.Both medicine pump assembly and die roll are automatic synchronized. It is convenient to adjust the

occasion of injection.

4.Medicine pump adopts the new type of cam to avoid manual timing operation

5.The injection wedge can stop at any positon, making the operation more convenient and quick.

6.The wiring position of heating cables is more reasonable.

7.The frame is of Al ,easy to lift and stedy use.

8.PLC-based control, touch monitor interface or switch button interface can be selected. The control system

can complete trouble diagnosis and reserve interface for remote diagnosis to upgrade.

9.Temperature control material hopper, precise temperature control, auto liquid level control, it is suitable

to various kinds materials requirements.

10.

The temperature adjustable material hopper assembly is equipped with the standard configuration. And

it can stir material refill material automatically, alarm for shortage of medicine.

PLC:

Automatic Gelatin Level Control System:

Samples:

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!