Automatic Encapsulation Machine For Paintball With Cooling Drum / 0.68" Paintball

Quick Detail

| Filling Tolerance | < ±1.5% | Material | 304 SUS |

| Application | Paintball Making for CS real man game | Weight | 600kg |

| Die roll size | Ф80X100mm | Capacity | 8000pcs/hour |

Product Description

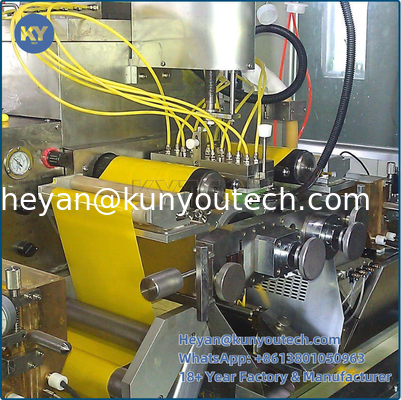

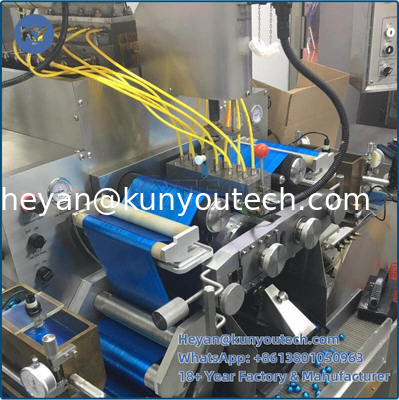

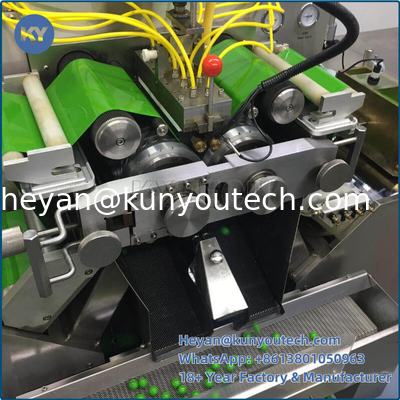

Our company is the first in China to export paintball equipment to North America which is capable of making tournament grade paintball, still the biggest paintball machine maker in China. Compared with the softgel machine, the paintball making need better machine accuracy, the drive transmission system is also precisely improved. The ancillaries are also modified correspondingly. The hopper and spreader box adopt level switch, making the level control more precise. Besides, the injection wedge, spreader box and hopper adopt the design of precise PID temperature control . The micro lubrication system largely reduce the consumption of paraffin oil.

Paintball making machine is used for making different color paintballs for game.

S403PB Paintball making machine is an experimental paintball machine designed especially for R&D department of laboratories, pharmaceutical factories in the universities and plant health products and Research Institutes.

1. The Gelatin Melting System

Water bath type gelatin tank is a special equipment for melting gelatin and production process. The gelatin melting tank has the advantage of compact structure, stable transmission and stable running performance. The mixing/stirring process is operated through connecting loop coupling and is composed of plurality of split agitator with stable transmission and better homogenization effect. The whole body of the tank is made of stainless steel. The body include three layers, including the tank liner, heating jacket and heat preservation layer. Heating the inner of the tank with the circulation hot water, it will be featured by fast heating, good thermal insulation performance, improving the quality of gelatin, accelerating the gelatin melting and shorten the melting time. The liner is closed totally with very good vacuum performance. The feeding mouth is convenient o assemble and repair. The whole tank is very smooth and bright with features of convenient cleaning, anti-corrosion and anti-acid, etc. Gelatin melting tank adopts stainless steel construction for its whole body. During its working process, the machine will suck moisture from inside of the tank, leaving the vacuum. All these are in accordance with the requirement of GMP. So the gelatin melting tank is an ideal equipment for the soft capsule pharmaceutical line.

Features of the gelatin melting

- Electrical heating

- Three layers(Thermal insulation and heating).

- Top compressed air supply.

- Stirring speed-----51rpm

- Weight:310kg

2. Specification for The Main Machine

| Die roll size | Ф80X100mm |

| Die roll speed | 0~5rpm |

| Overall dimension | 1250×400×2300mm |

| weight | 600kg |

| Power supply | 380V/240V,50/60HZ |

| Power of the main motor | 1.1kw |

| Power of the main machine | 3kw |

Competitive Advantages

- Small size, low energy consumption

- Easy to operate and clean

- High precision

- Small load difference

- Micro lubrication

- High quality and intelligence control system, PLC true color touch screen technology adopted by the electronic control system. All electric parts use world brand parts, such as Siemens, Schneider.

- The hopper can keep medicine temperature steady, more suit to fill suspension into the paintball.

- Air-cooling system is adopted at the output of paintball, that make paintballs amazing

- Professional PID temperature control technology is adopted on the machine, temperature of injector can be adjusted accurately. Improves ratio of finished products of paintball.

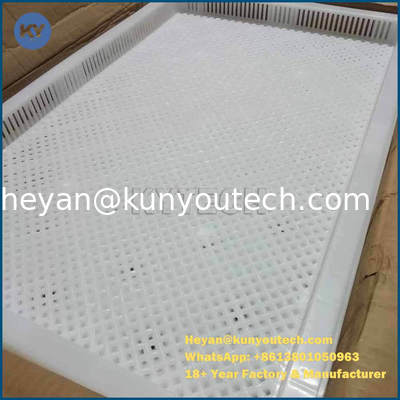

3. The Tumble Drying System

TD-2 Soft Capsule (Softgel) and paintball Tumble dryer is used to predry and initial shaping of soft capsule (softgel) and paintballs. Each section can be of variable frequency of speed regulation. There should be two tumble dryers at least, we call it one group. In other words, your making machine should be equipped with one group of tumble dryer(two sections) at least. Each section is equipped with an independent fan to make softgels and paintballs distribute evenly, thus making the drying effect much better. Each dryer can be easily removed and easy to clean, it’s more in line with the requirements of GMP. Each dryer is equipped with electrostatic guiding device and safety production device. The operator can conveniently make the dryer stop just in the tumble dryer position. TD2 has advanced structure and stable material, making its drying effect much better than other models of domestic and Korean machine.

The baskets number of drying machine should be fit for the main machine. We have TD-0, TD-1,TD-2, TD-3 and TD-4. five models. And S403PB Paintball making machine is suitable for small scale production, so TD-2 is better suitable.

The specification for the Tumble Drying Machine

| Model | TD-0 | TD-1 | TD-2 | TD-3 | TD-4 |

|---|

| Basket diameter(mm) | 420 | 580 | 580 | 730 | 526 |

| Basket length(mm) | 620 | 600 | 900 | 1010 | 282 |

| Drying fan(kw) | 0.25 | 0.32 | 0.32 | 0.55 | 2 |

| Motor Power(kw) | 0.2 | 0.4 | 0.4 | 0.75 | 1.5 |

| Basket per section | 1 | 2 | 2 | 1 | 6 |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!