Company Information

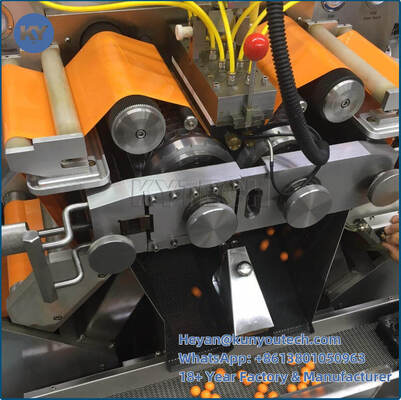

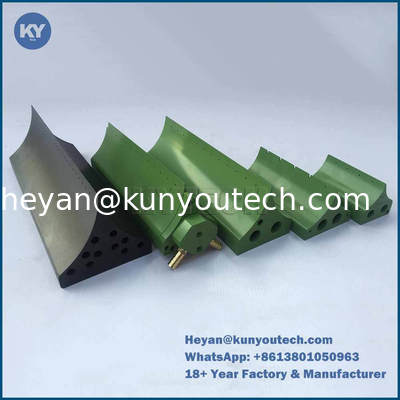

S610 roll type soft capsule’s key parts of the machine select Germany precision bearings. The whole machine’s mechanical parts adopt independent single adjustable lubrication, reducing mechanical wear and prolonging the time without any mistakes. The drug pump can run together with the die roll automatically and synchronously, it’s very convenient to adjust the spraying time. S610 adopts a new cam mechanism, which relieved the reversing board manual synchronization process. There are two ways which use the cantilever to operate, large size touch screen and switch button to choose from. The control system has faults diagnosis function. It can realize remote diagnosis after the upgrade. New 8 type amorphous drying roll cage is charactered by variable frequency speed regulation and more reasonable structure. The cage can be disassembled without moving dryer. It’s easy to clean. There are material receiving discs under the roll cage, making S610 more in line with the requirements of GMP. S610 roll type soft capsule automatic production line is used to press and inject the oil liquid, suspension liquid or paste quantitatively and encapsulated them in the gelatin, then producing different sizes and different shapes of the sealing softgels. The production line is mainly composed of main machine, tumbler dryer, fill material system and pneumatic theroms plastic barrels, etc.

Specifically speaking, it has the following characteristics:

Dosage deviation:<+1.5%

Gelatin ribbon lubrication: paraffin oil or fractionated coconut oil, less than 1kg in 8 hours. Solvent free.

Major bearing made in Germany.

Capsule brushes are driven by independent motor to prevent the gelatin stuck into the die roll cavity.

Separate lubrication system for medicine pump and die roll assembly.

Water cooled drum also have air blowers

PLC and touch screen control with self-trouble diagnostic.

Automatic medicine supply. The system can even alarm when the fill material tank is empty.

High accuracy medicine pump. The diameter tolerance of the 20 plungers are less than 0.005mm.

Specification

|

Model

|

S610

|

|

Die roll size

|

150×250mm

|

|

Die roll speed

|

0~5rpm

|

|

Max plunging volume per stroke

|

0~2ml

|

|

Plunger numbers

|

20/24

|

|

Overall dimension

|

2050×1200×1850

|

|

Weight of main machine

|

1900kg

|

|

Power consumption

|

13.5kw

|

|

Control mode

|

PLC+Touch Screen

|

|

output

|

8#OV120000 pcs/hour

|

Packing&Shipping

We pack the whole machine with wooden case and pack the softgel die roll and paintball die roll with standard boxes.

We ship the whole line of macine by ocean through the freight agent.

Our services

We not only provide the whole paintball & softgel making machine line, but also can provide the factory design for you. In terms of the after-service, we will be responsible for such services as belows: maintenance, parts supplying, technical support.

If you are interested in our products, please feel free to contact us. Welcome!

Product samples.

FAQ

Q1:Are you factory or trading company?

A: We are factory and manufacture.

Q2: Where is your factory located? How can I visit your factory?

A: We are located in Beijing, you can fly to Beijing airport or Nanyuan airport. Wecan pick you up from the airport or your hotel.

Welcome to visit us!

Q3:How to place my order?

A: Just contact us via TraderManager, E-mail, Skype or telephone to confirm the product, make the deposit then we will start to manufacture.

Q4 : What is the payment term?

A: 30% T/T deposit and 70% T/T balance payment before shipping.

Q5:How long is the delivery time?

A: About 35- 40 working days.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!