Tumble dryer for softgel capsule in high efficency and speed

TD-2 Tumble Drying Machine Parameter

| Model |

TD-2 |

| Internal Diameter of Basket |

580 mm |

| Basket Length |

900 mm |

| Fan Power |

0.32 kW |

| Motor Power |

0.40 kW |

| Rotary Speed |

0-25 rpm |

| Basket Quantity per Section |

2 |

| Fan Delivery |

>2500 m³/h |

| Loading Capacity per Basket |

>20 kg |

Feature and Advantage

We pay great attention to the combination of design and application, and focus on improvement of production efficiency and stability. The major advantages of our tumble dryer are as below:

1. Basket:

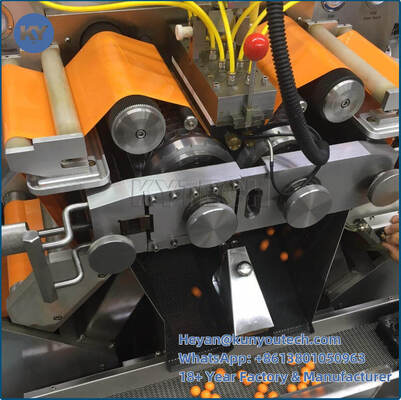

1.1 Basket is the most important part of tumble dryer, net of basket is made from SS304/316 wire, meet GMP requirement. The special fabrication processing ensures the inner wall of basket is smooth and burrs free. Capsules will not be damaged or turn into black color.

1.2 The inside guide plates are designed as unsymmetrical construction to ensure capsules be dispersed evenly. To compare with conventional slanted guide plate design, this design effectively avoid capsules be cumulated on one side of basket.

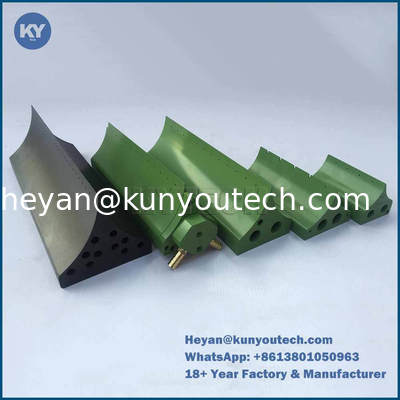

1.3 The angle and arc of guide plates are precisely calculated, and the plates are molded in customized special mold. Capsules fall down after being lifted by the guide plates to a certain height. The time of capsules being dried in wind is longer, drying effect is obviously better than other brand product.

1.4 The outlet of tumble dryer adopts bevel angle and arc transitional streamlined design, and is molded by customized mold too. Capsules will come out smoothly and will not stick on it.

1.5 The end part and gear of the basket are made from FDA approved polymer material HMWPTFE (High molecular weight PTFE), the friction coefficient is super low, thus avoid adhesion with capsules, this is superior to normal nylon materials very much.

1.6 The frame of basket is in compact design, rigidity is high, and the construction is stable.

1.7 With both manual and auto control modes. Under auto control mode, each basket will rotate forwardly or backwardly according to the time set by operator.

2. Electrical Parts

2.1 All the contactors, relays, breakers, switches and knobs are Schneider brand. Control system adopts PLC control.

2.2 There’s a static electricity guiding device on each basket.

2.3 The safe protection function will ensure basket stop rolling when the cover is open, and back to rotate after close the cover.

2.4 There is a discharge alarm lamp on the last section of tumble drying machine, which flickers 12 seconds before discharge to remind the operators.

2.5 Each basket equipped with an independent drying fan.

2.6 Each basket equipped with frequency convertor, running smoothly and speed can be adjusted independently.

2.7 Our machine has a unique full-start function, this function is very useful when need to restart the machine in case of accidental power cut.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!