Precisional Electric Pharmaceutical Machine For Food / Softgel Making

Quick Detail

| Product Name |

Large scale Softgel encapsulation machine |

Driven Type |

Electric |

| Capacity |

120000pcs /hour, 8#OV |

Dosage deviation |

<±1.5% |

| Application |

Food, pharmaceutical,softgel making machine |

Control |

PLC |

Product Description

S610 soft capsule encapsulation machine is suitable for lage scale capsule production. Micro lubrication saves much cost for customers. This machine adopts advanced technology and good quality material.

Soft capsule encapsulation machine can be used to make all kinds of soft capsules: Oval, Oblong, Round, Tube,etc.

Specification

| Model |

S610 |

| Die roll size |

150×250mm |

| Die roll speed |

0~5rpm |

| Max plunging volume per stroke |

0~2ml |

| Plunger numbers |

20/24 |

| Overall dimension |

2050×1200×1850 |

| Weight of main machine |

1900kg |

| Power consumption |

20 kw |

| Control mode |

PLC+Touch Screen |

| output |

8#OV115,440 pcs/hour |

Automatic Softgel Making Machine, Soft capsule Encapsulation Machine, Paintball Encapsulation Machine

Product Description

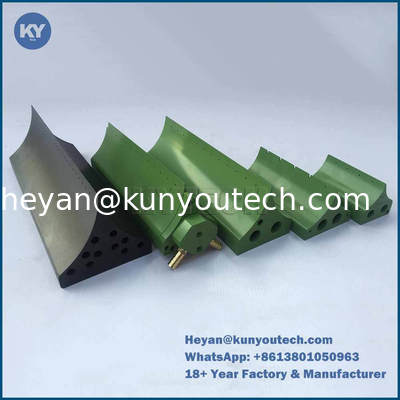

Our company is the first in China to export paintball equipment to North America which is capable of making tournament grade paintball, still the biggest paintball machine maker in China. Compared with the softgel machine, the paintball making need better machine accuracy, the drive transmission system is also precisely improved. The ancillaries are also modified correspondingly. The hopper and spreader box adopt level switch, making the level control more precise. Besides, the injection wedge, spreader box and hopper adopt the design of precise PID temperature control . The micro lubrication system largely reduce the consumption of paraffin oil.

Softgel making machine,Soft capsule making machine,Soft capsule encapsulation machine,Softgel machine,Soft capsule manufacturing machine

What is the specifications of Automatic Soft'gel encapsulation machine ?

Model S610 soft-capsule production line is a new generation of rolling-mold water-cooled soft-capsule line optimally designed and finely manufactured on the basis of foreign latest technology.

Its main technical specifications reach the international advanced level and conform to standard GMP.

Model S610 soft-capsule production line consists of the gelatin-melting pot, thermal-insulated gelatin-storage pot, electrical control panel, main machine conveyor, setting-drying rotary-cage, ruptured-gel recovery unit, and colloid mill. It works under the following principles.

The oily or gelatin-insoluble liquids, pastes, or plasters (e.g. extract form Chinese Medicine Herbs) are injected into between two rolling gelatin skins in a given quantity, cut, and then formed through two rolling molds into various-shaped soft-capsules, such as egg-shape, fish-shape, cylindrical shape ball-shape and calabash. These products are widely used in many industries such as medicine, cosmetics, health goods and pesticides.

This production line offers the following ten merits:

- The water-cooled models eliminate the dust contamination resulted from the air-cooling.

- In comparison with 6-inch model the optimized rolling-models increase the output by 30%-40% and meanwhile remarkably enhance the utilization ratio of gelatin.

- The gelatin is pneumatically conveyed from the thermal-insulated gelatin-storage pot through the ground, which improves the production environment.

- The food-grade conveyance belt produced by Lexno Corporation (USA) (FDA an approved) is used for conveyance of capsule, which is non-toxic, non-sticky, and easily washable.

- The setting-drying rotary cage is made of stainless steel expanded sheet, which is free of dead corners and easily washable. An oil pan is placed under the rotary cage to ensure a working environment free of oil drops.

- All the electric elements are imported from famous manufacturers and have stable performances.

- In production of low-dosage products, the accompanied 10-station and 14-station injection rod fully utilizes the width of molds and enhances the gelatin-utilization ratio and output.

- The optimal-designed injector extends the range of consistency of medicine solution.

- The improved capsule-peeling unit minimizes the probability of wrapping of the waste gelatin skin onto the gelatin-peeling rod.

- Except that the injector, the spreading box and the rolling-mold conveyance belt are made of special materials, the parts contacting with medicine are made of 304 or 316 superior stainless steel and absolutely conform to standard GMP.

- High quality and intelligence control system, PLC true color touch screen technology adopted by the electronic control system. All electric parts use world brand parts, such as Siemens, Schneider.

- The hopper can keep medicine temperature steady, more suit to fill suspension into the paintball.

- Air-cooling system is adopted at the output of paintball, that make paintballs amazing

- Professional PID temperature control technology is adopted on the machine, temperature of injector can be adjusted accurately. Improves ratio of finished products of paintball.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!